4065 N. Woodlawn #4 || Wichita KS || 67220 || (316) 681-3566

Ship Building: Plate and Bulkhead Heating by Induction

Shipbuilding, both military and commercial, required plate straightening before and after seam arc welding. Traditionally, gas torch heating was used. Induction heating, which features flameless heating and superior temperature control, is the favored method.

|

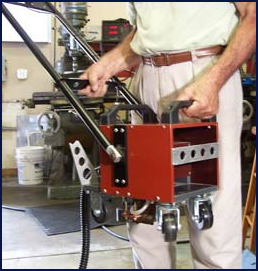

Roll-around unit is not much larger than a vacuum cleaner yet can lay down 30KW of induction power in 75 mm diameter circles or in heated linear strips. |  |

| Heating unit weighs 15 kilos and can be easily transported. |

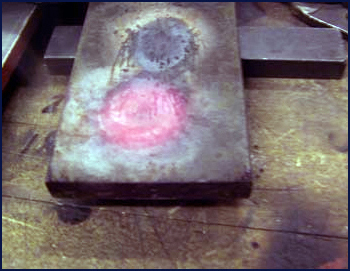

12mm plate heated in 20 sec's. Note: manner in which heat can be concentrated in specific areas. |

High output rose bud gas torch heating the same plate in the same time period with minimal effect. |

|

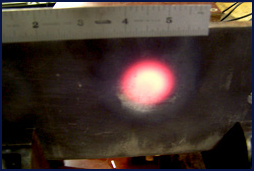

Shown is the effect of thru heating 1/2" steel plate. Heating coil is mounted on opposite side for this demonstration. Try as you might with a gas torch, you won't achieve this type of pin-point heating. |